Type of Laboratory

A light laboratory that also features a heavy equipment

Lab manager

Staff

Filippo Marchelli

Roberta Ferrentino

Giulia ischia

Giovanni Lenardon (tecnico part-time)

Activities

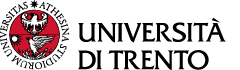

The Biomass Laboratory (LB) was established to valorize residual biomass and organic waste to derive substances and materials of interest in the energy, environmental, agricultural, green chemistry, food and nutraceutical fields. The concept that inspires the LB is that of circular economy, declined in process and plant innovation and biorefinery.

The LB was established in 2004 for the valorization of agro-industrial residual biomass (e.g., residual wine-making marc, fish processing waste) as a source of compounds and molecules of food interest: oils, omega-3, polyphenolic compounds, antioxidants, and bioactive. It is operated by means of supercritical CO2 extraction technology, as well as by traditional methods.

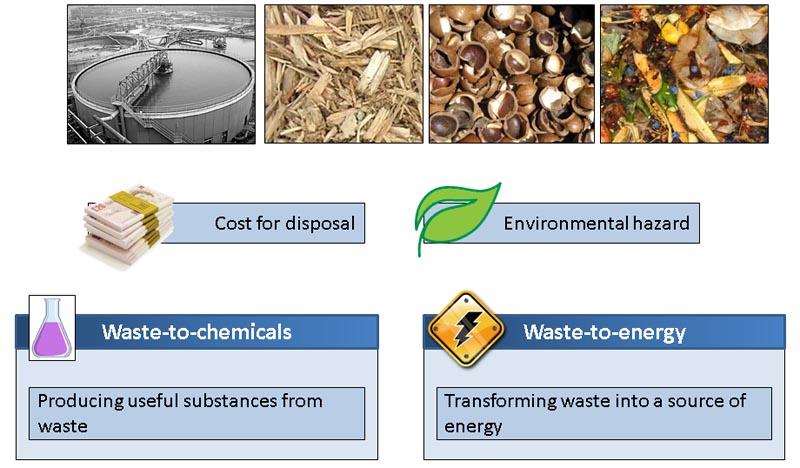

A few years later, new lines of research were developed within the LB in the area of energy engineering and recovery of materials with environmental value: solid (biocarbon) and gaseous (biogas) energy carriers, adsorbent materials (activated carbon) and agricultural use as a source of C and macronutrients (N, P, K: fertilizers and soil conditioners), molecules of interest for green chemistry (platform chemicals). Biomass and organic wastes are converted via hydrothermal conversion, in the presence of water in the liquid state: thermal hydrolysis and especially hydrothermal carbonization (HTC). With HTC, operating at temperatures in the range of 180-250 °C (P 10-50 bar), in a few hours the carbonization process that takes place in nature over geological eras is achieved. Through collaborations with partner laboratories present within DICAM, the processes of anaerobic digestion, composting, and adsorption for water remediation are also studied. The approach is typical of process engineering: new integrated processes (biorefinery, process symbiosis) are developed to innovate, intensify, and make efficient industrial processes with a view to material and energy recovery.

Location

Basement floor - room 7

Info

The research and activities of our team are focused on the development of new technologies in the Waste to Energy and Waste to Chemicals sectors.

Our competencies in process, chemical, and industrial engineering make our research activities focused on real-life cases. The aim is valorising biomasses, such as agro-industrial residues and organic wastes, through experimental tests and process modelling simulations. By combining them, we are capable of simulating chemical-physical phenomena at lab- and industrial-scale levels. Among all the technologies available for biomass thermochemical conversion (e.g. gasification, dry pyrolysis, combustion), we particularly deal with hydrothermal processes: supercritical water gasification and, especially, hydrothermal carbonization.

We have also high-level expertise in the food engineering sector. In this field, our research principally concerns the extraction of nutraceuticals (omega-3, antioxidants, food oils) contained in food residues by using supercritical CO2 or alternatively, classical chemical solvents or mechanical pressure.

HydroThermal Carbonization

HydroThermal Carbonization (HTC) is a thermochemical process for organic waste conversion into valuable products. During HTC, the organic matter in an aqueous suspension is transformed in a short time (1-3 h) at moderate temperatures (180-250 °C) and pressures (10-50 bar) in a solid carbonaceous material, named hydrochar.

Application

Hydrochar has different applications:

- Sustainable biofuel with a high heating value (25-30 MJ/kg). It can be used in the form of pellets in domestic stoves or in district heating boilers;

- Soil improver;

- Precursor for activated carbon;

- Precursor of catalyst;

- Carbonaceous material for fuel cell electrodes.

Treated biomass

The HTC process is suitable for high moisture residues (>50 wt. %):

- Organic fraction of municipal solid waste (OFMSW);

- Agro-industrial residues (e.g. vine and oil processing by-products, manure, orange pomace…);

- Pruning residues;

- Sewage sludge;

- Digestate (from anaerobic plant).

Advantages of HTC

- It is a CO2-neutral process;

- It is adaptable to a small-scale industry context;

- It could be implemented easily in existing plants (composting and anaerobic digestion plants);

- The biomass can be used as it is, without pre-drying;

- It is a simple and fast technology.

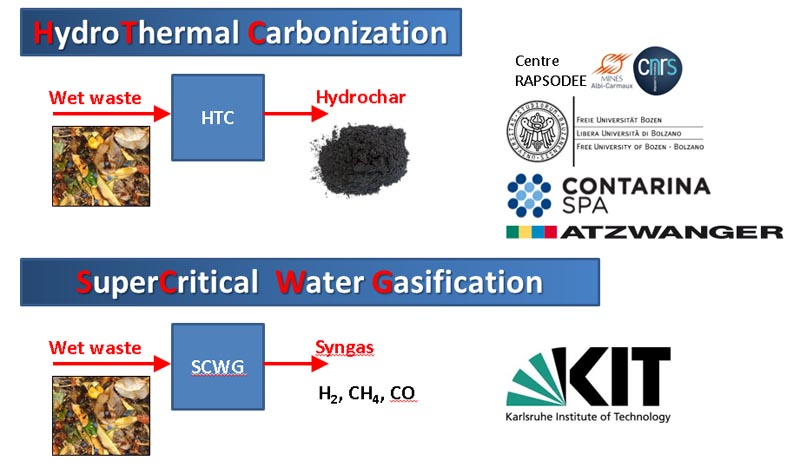

Supercritical CO2 Extraction

Concerning the food engineering field, we use supercritical CO2 (SC-CO2) as a solvent for the extraction of biochemical products for food, pharmaceutical, and cosmetic sectors.

Substrates utilized

- Grape marc;

- Seeds;

- Agro-industrial waste;

- Fish processing by-products;

- Medicinal herbs.

Extracted bio-based substances

- Natural antioxidants (e.g. polyphenols);

- Grape seeds oil;

- Omega-3 enriched oil;

- Caffeine (in the case of decaffeinated coffee).

Advantages of SC-CO2

- CO2 is not toxic

- CO2 is not flammable;

- CO2 is ecologically sustainable;

- For the highest quality of extracts obtained with respect to the other extraction technologies, SC-CO2 extraction is used especially for high added-value extracts.

Moreover, we are specialized in SC-CO2 fractionation. We apply this technique for obtaining omega-3-enriched concentrates starting from fish oil.

Laboratory equipment

Our lab is equipped with:

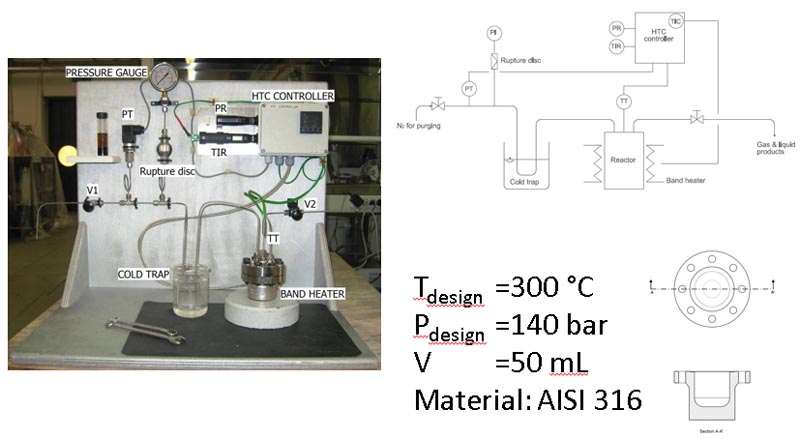

- Lab scale HTC reactor (Working volume: 50 mL; design pressure: 140 bar; design temperature: 300 °C; material: AISI316).

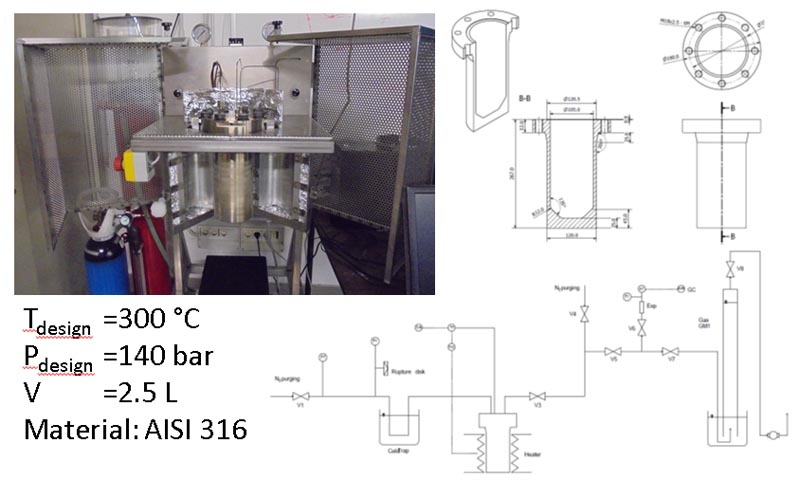

- Bench scale HTC reactor (Working volume: 2.5 L; design pressure: 140 bar; design temperature: 300 °C; material: AISI316). The reactor is monitored and controlled by software developed in LABView programming language.

- Calorimeter for HHV measurement.

- Elemental analyzer for elemental composition (C, H, O, N, S) determination.

- Supercritical CO2 extractor (Working volume: 500 mL; design pressure: 600 bar), equipped to work also with organic co-solvent (e.g. ethanol).

- Soxhlet extractor, used with organic solvent (ethanol, hexane…).

- Mechanical extractor;

- Vacuum rotary evaporator;

- Ovens, thermos-balance, grinders, vibrating screen.

Publication:

https://scholar.google.it/citations?user=0FxUZEIAAAAJ&hl=it&oi=ao